What is Warehouse Automation?

In the fast-paced world of modern logistics, warehouse automation has become a critical competitive advantage. By leveraging a variety of technologies and solutions, warehouses can streamline operations, improve accuracy, and enhance productivity – ultimately delivering a better customer experience.

But what exactly is warehouse automation, and how can it transform your warehousing and distribution capabilities?

The Fundamentals of Warehouse Automation

At its core, warehouse automation refers to the use of technology, equipment, and software to automate manual, repetitive tasks within a warehouse or distribution center. The goal is to reduce human intervention and error in core warehousing processes, such as:

- Goods receiving and put-away

- Inventory management and tracking

- Order picking, packing, and shipping

- Material movement and transportation

Warehouse automation solutions can range from basic barcode scanners and warehouse management systems to highly advanced robotics, autonomous mobile robots, and AI-powered optimization.

The Benefits of Automating Your Warehouse

By embracing warehouse automation, companies can unlock a wide range of tangible benefits, including:

- Improved Productivity – Automated systems can execute repetitive tasks faster and more consistently than manual labor, increasing overall throughput.

- Enhanced Accuracy – Automation eliminates the risk of human error in areas like order picking and inventory management.

- Increased Efficiency – Automated solutions optimize workflows, reduce travel times, and minimize unnecessary motions and steps.

- Better Visibility and Control – Warehouse management systems and other automation tools provide real-time data and insights to drive continuous improvement.

- Increased Safety – Many automated solutions, like autonomous material handlers, can reduce workplace injuries and accidents.

- Cost Savings – While the upfront investment can be significant, automation often yields long-term reductions in labor, inventory, and operational costs.

Warehouse Automation in Practice

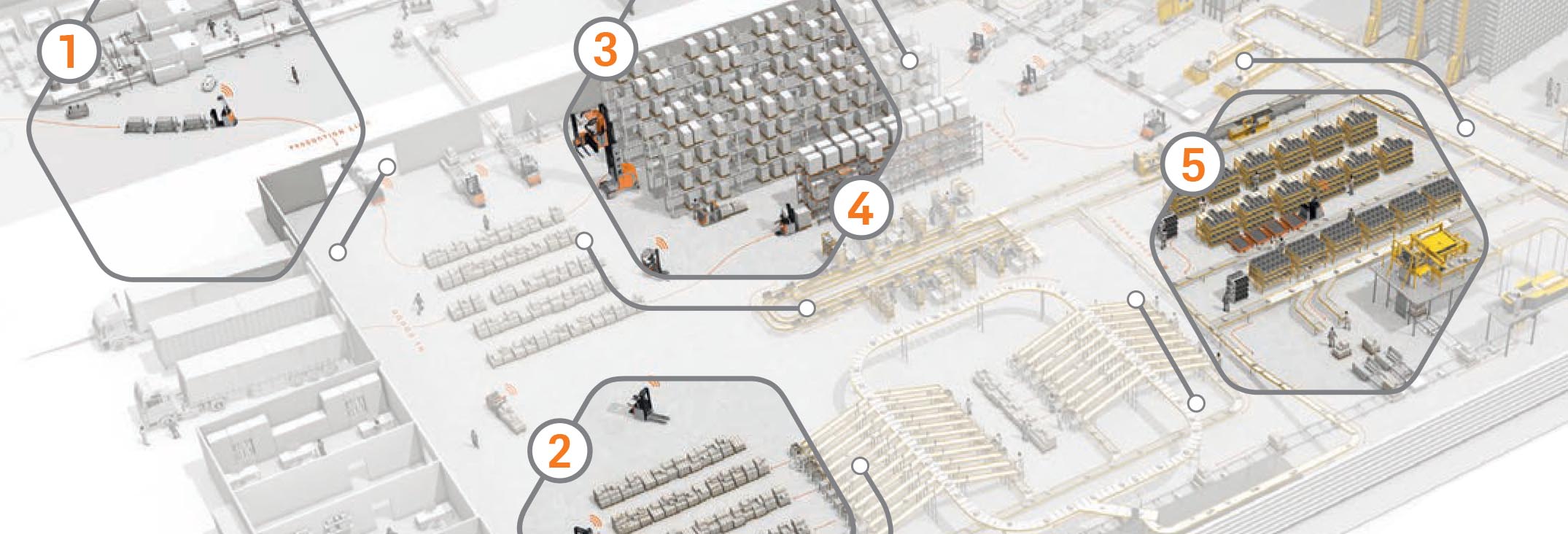

The specific warehouse automation technologies a company deploys will depend on the nature of their operations, product mix, and business objectives. Common automation solutions include:

- Automated storage and retrieval systems (AS/RS)

- Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs)

- Robotic picking and palletizing systems

- Warehouse management software and WMS integrations

- Inventory tracking via barcode, RFID, and other sensors

By strategically implementing the right mix of warehouse automation tools, companies can transform their warehousing capabilities, enhance customer service, and gain a powerful competitive edge.

Ultimately, warehouse automation is about using technology to optimize human effort, minimize errors, and create a more efficient, responsive, and profitable warehousing operation.

Want to know more? We’re here to guide your operation to efficiency!

Request Consultation

"*" indicates required fields